We have been specialising in the plugging resins business since 2007 and have accumulated more than 17 years of production and technical experience in the field.We have a professional technical team to provide customers with a full range of services.In order to ensure that the quality of products and environmental management meet international standards, we have passed the ISO9001 and ISO14001 system certification.Meanwhile, we have introduced advanced foreign hole plugging, grinding and AOI inspection equipment. We have established R&D centres for vertical hole plugging and precision grinding of semiconductor IC-Substrate PCB in South China and East China, and provide customized solutions according to customers' needs. We can provide a complete set of resin plugging solutions such as selective hole plugging, whole board hole plugging, multiple hole type hole plugging, hole plugging and grinding of metal substrate, etc. We are committed to providing customers with high quality and competitive price.

Plugging of holes

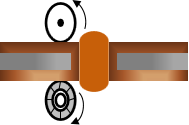

★MASS GmbH and domestic SetSense vertical vacuum hole plugging machines are used.

★Solves high aspect ratios, bubble problems and eliminates the need for jigs.

★The paste plug head can continuously pressurise the paste supply and has a high hole-entry capacity.

Selective Plugging Foundry

★High machine stability, ES automatic balancing.

★Visual screen to monitor the plugging process.

★Mesh panels can be pulled out for easy cleaning and maintenance.

★Completely solves the problem of bubbles and voids in high aspect ratio boards.

Processing Capability

NO. | Items | Plate Plugging | selective hole plugging | remark |

1 | Production Size | 250*250mm-610*760mm | 250*250mm-610*710mm | Exceeding specifications requires engineers to reassess feasibility. |

2 | Panel Thickness | 0.2-8.0mm | 0.2-8.0mm | Exceeding specifications requires engineers to reassess feasibility. |

3 | diameter of hole | Drilling diameter 0.15-0.8mm Max. plug hole diameter to panel thickness ratio 1:1 | Drill hole diameter ≥ 0.15 | Exceeding specifications requires engineers to reassess feasibility. |

4 | copper-cladding thicknesses | Incoming copper ≥25μm. Plating hole filling grinding copper needs to be ≥30μm | copper-clad≥15μm | Substrate leakage below 15μm is extremely risky. |

5 | Aspect Ratio | Through hole 40:1 Blind hole 1:1 | Through hole 40:1 Blind hole 3:1 | Exceeding specifications requires engineers to reassess feasibility. |

6 | leave a margin at the edge of the board | Plate edges to be at a distance from the plug holes ≥15mm | not required | One side of the plate ≥15mm is sufficient |

7 | Safe Hole Distance | - | Hole edge distance ≥0.3mm | Exceeding specifications requires engineers to reassess feasibility. |

8 | the large and small holes | Extreme difference in size of neighbouring holes <0.3mm | Single PNL inner aperture extreme: <0.3mm | ≥0.2mm Using two plug holes |

9 | Copper Reduction | Copper reduction for flatness of the board 3-5μm | - | Above 8μm, separate copper reduction is required. |

Grinding subcontractor

★With three multi-axis grinding lines.

★We have extensive experience with thin and thick plates.

★The special design of staggered arrangement of ceramics reduces the accumulation of copper sludge and chips caused by brush wheel abrasion.

★Panel Size:250-250mm-610*760mm.

Plugging process introduction

Pre-treatment washing,pre-baking and drying |  |

Plug holes panel using vacuum screen |  |

Curing Bake in sections to make the paste heated more evenly and avoid cracking. |  |

Grinding Remove excess plugging ink with a ceramic brush + non-woven cloth. |  |

| Check:AOI、visual examination |  |

NO. | Plug Hole Types | Materials | Photos | Remark |

1 | mixed pressure + high frequency and speed + back drilling | teflon+FR4 |

| Panel thickness:1.6mm. Plug hole aperture: 0.4mm. Back drilling depth: 0.9mm. |

2 | multilayer | FR4 |  | The number of layers of this board is 32 in total. The panel thickness is 8.0mm, the copper of the finished hole is 0.10mm, and the aspect ratio is 80:1. |

3 | Blind + Through + Buried + Back Drilled | FR4 |  | Hole diameter: 0.3mm. Depth: 0.3mm. |

4 | Buried hole + through hole + HDI | M6 |  | Aspect Ratio:40:1 |