VCP3050

The largest of the vertical plugging machines.

Descriptions

Specifically designed for the development of oversized circuit boards; the use of vacuum principles to achieve conductive and non-conductive resin paste hole plugging process, suitable for a variety of types of holes plugging process for the entire board, and can be applied to resin, silver paste, copper paste and conductive adhesive and other materials.

Features

★It's possible to realise the process of plugging holes for oversized 30*50ln (762*1270mm) circuit boards.

★Flexibility to realise: through holes, blind holes on one or both sides, back drilled holes, etc. on the same board surface.

★For high density BGA on circuit boards.

★Ideal for small quantities and a wide range of gauges, no fixtures or air guides are required for hole plugging.

★The operating interface is automated, user-friendly and easy to operate.

Product Specifications

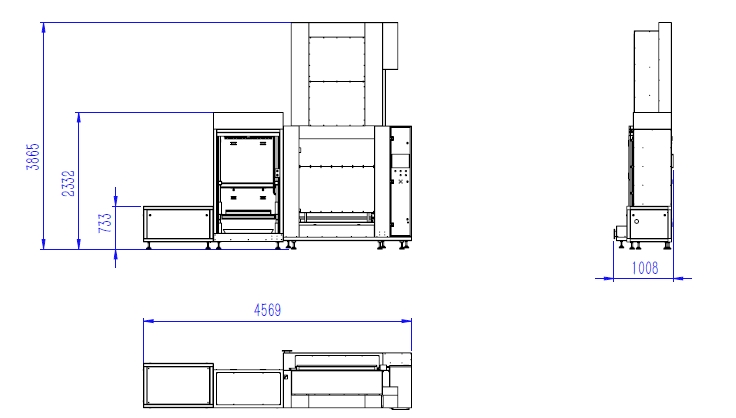

Machine Size | 4569*1008*3865mm |

Vacuum | ≤ -0.99bar/-99kpa (at standard atmospheric pressure) |

Panel Thickness | 0.2-8mm |

Panel Size | MAX:30寸*50寸(762*1270mm) |

Maximum operating plate weight | 20kg(Max.) |

Through Hole, Plugging Hole thickness to Diameter Ratio | Through hole: 40:1 (Max.) Blind hole: 1:1 (Max.) |

Plugging Methods | Full Plate Plugging Holes |

Plugging speeds | 0-75mm/sec(adjustable) |

Plugging Pressure | 0-7bar(adjustable) |

Diametr of plugging holes | Through hole: 0.1-1.0mm (hole diameter after plating) Blind hole: 0.1-1.0mm (hole diameter after plating) |

Noise (normal operation) | ≦75dB |

Paste Pressure | Atmospheric Pressure:0-6bar(adjustable) |

Plugging holes and plate edge spacing | Hole distance from board edge:≧15mm |

Operation Panel | Touch-screen operation |

Protection devices | Safety grids, emergency stops |

Vacuum suction method | Oil vacuum pumps |

Paste Addition Methods | Automatic refill system or single paste clip replacement |

Failure Rate | ≦1/400h(Failure time/equipment uptime) |

Height of operating table | 1855±100mm |

Production Capacity(normal speed)

Take 30"*50" as an example, thickness to diameter ratio of 10:1, through-hole plate (single-sided) capacity of 10 pieces / hour.

Communal Requirement

Electrical requirements | |

Electric | Three-phase five-wire 380V |

Pressure of compressed air | ≧7bar |

Weight | 1800KG |

Equipment installation environment (temperature, humidity and dust-free requirements) | A. Environmental requirements: clean room,100,000 level↑. B. Temperature requirement: 22±2℃. C. Humidity requirements: 50±5% |